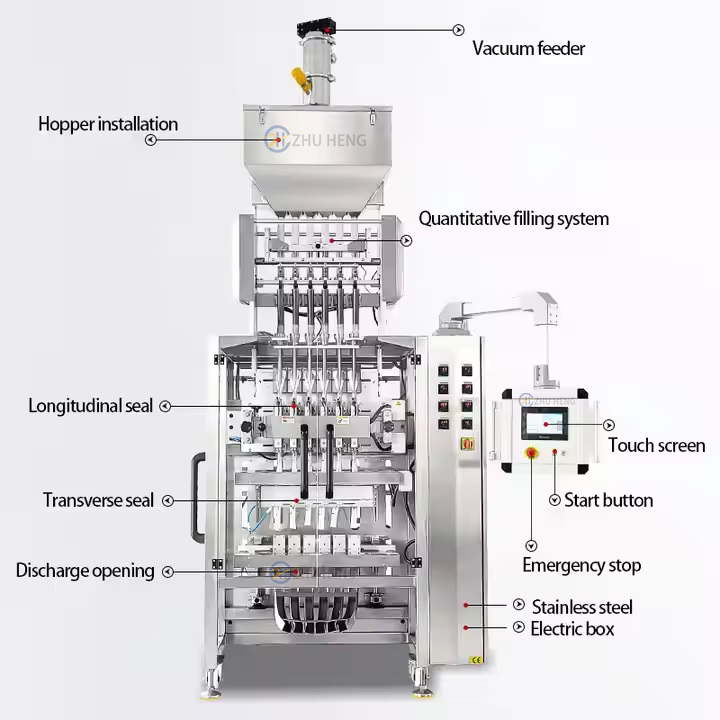

Multi-lane packing machine is a high-speed automated machine that fills and seals pouches or bags with products like powders, liquids, granules, or sauces. They are ideal for situations requiring large volume production and can significantly improve efficiency by reducing labor costs.

Here are some key characteristics of multi-lane packing machines:

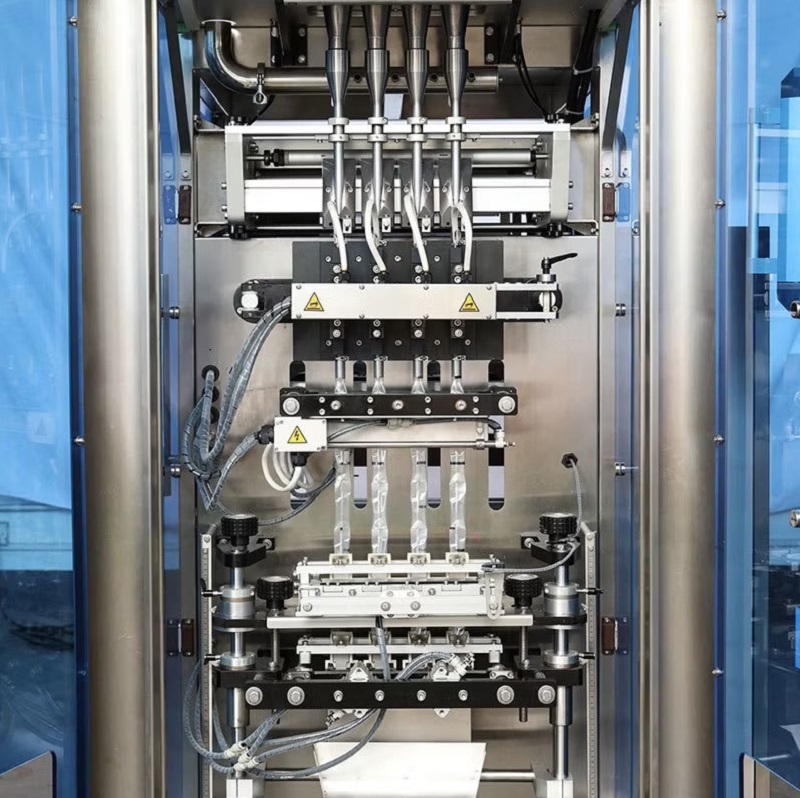

Multiple Lanes: As the name suggests, these machines have multiple lanes that operate simultaneously. This allows them to fill and seal many pouches or bags at once, significantly increasing production speed compared to single-lane machines. The number of lanes can range from 2 to 16, with more lanes enabling faster output but also making the machine more complex and expensive.

Versatility: They can handle various products including powders, liquids, granules, and sauces. Different filling systems are employed depending on the product characteristics (flowability, consistency, etc.)

Automation: The entire process, from film unwinding (for VFFS machines) to pouch discharge, is automated. This minimizes manual labor and ensures consistent filling and sealing.

There are two main types of multi-lane packing machines:

Vertical Form Fill Seal (VFFS) machines: These machines create a pouch from a roll of film, fill it with product, and then seal it. They offer high versatility in terms of pouch shapes.

Pre-made pouch machines: These machines fill pre-made pouches with product and then seal them. They are generally faster than VFFS machines but less versatile.

Overall, multi-lane packing machines are a powerful solution for automating high-volume production of various products in pouches or bags.