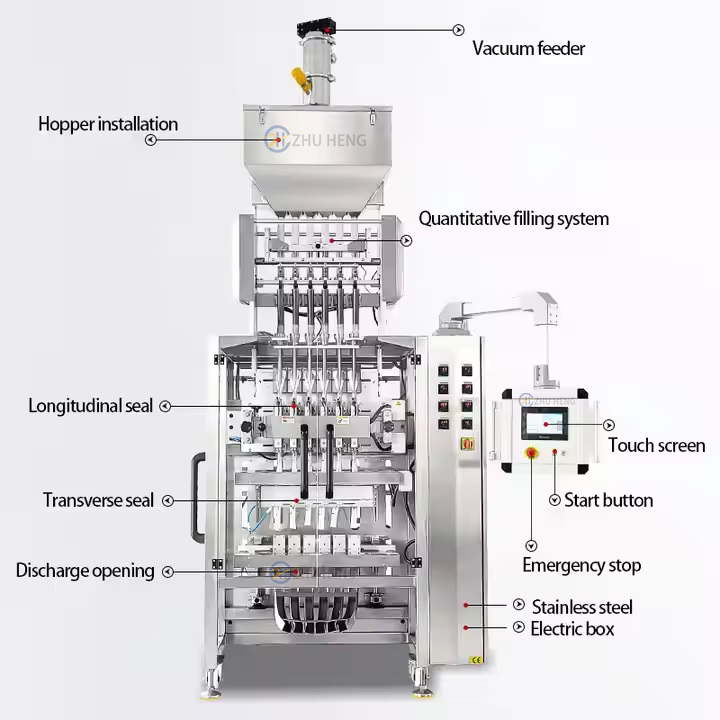

12-Lane Packaging Machines are designed for high-speed, single-serve packaging of powders, granules, liquids, and semi-solids. Multi lane stick pack machine is ideal for medium to high-volume production, offering efficiency and precision.

1. Key Features of 12-Lane Stick Pack Machines

✔ High-Speed Production – Typically 300–720 stick packs per minute (depending on product).

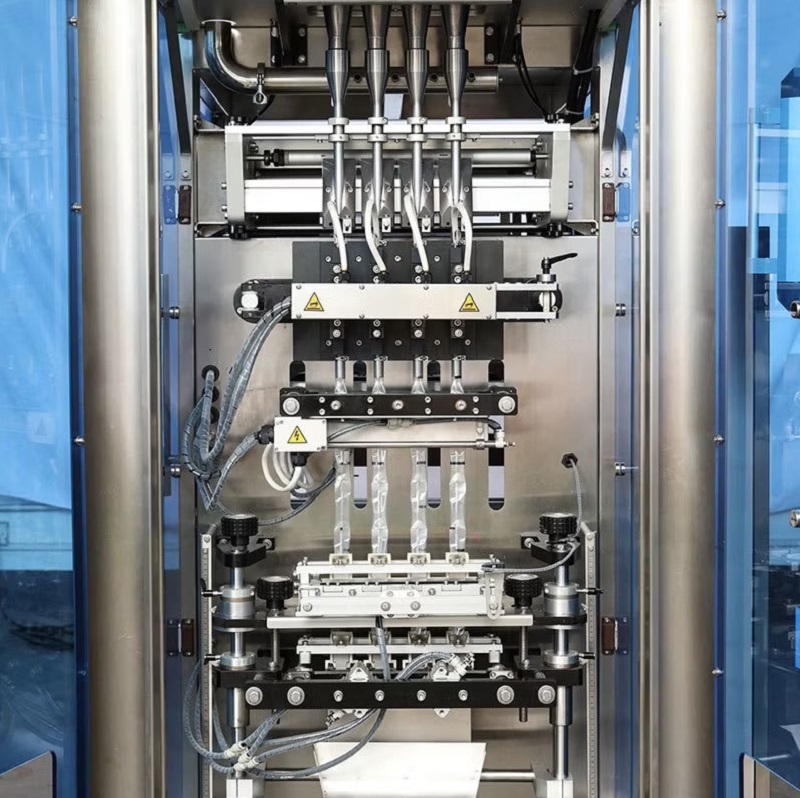

✔ Multi-Lane Design – 12 parallel lanes for simultaneous filling, increasing output.

✔ Flexible Packaging – Handles various stick pack sizes (e.g., 10–200mm length, 5–25mm width).

✔ Material Compatibility – Works with laminated films (PET/AL/PE, OPP/PE, etc.) for moisture & oxygen barrier.

✔ Precision Dosing – Volumetric or auger fillers for powders, liquid pumps for fluids.

✔ Sealing Options – 3- or 4-side sealing, ultrasonic sealing for sensitive products.

✔ Easy Changeover – Quick-adjust systems for different stick pack sizes.

Multi line Stick Pack Packaging Machines

2. Applications

✅ Food & Beverages – Coffee sticks, sugar, creamer, drink mixes.

✅ Pharmaceuticals – Oral rehydration salts, effervescent tablets, supplements.

✅ Cosmetics & Personal Care – Single-use shampoo, face masks, serums.

✅ Chemicals & Industrial – Detergent powders, lubricants, adhesives.

3. Advantages of 12-Lane Stick Pack Machines

🔹 Higher Productivity – 12 lanes = 12 sticks filled at once, reducing cycle time.

🔹 Lower Cost per Unit – Efficient material usage and reduced labor costs.

🔹 Compact & Hygienic – Smaller footprint than sachet machines, easy to clean.

🔹 Customizable – Optional features like date coding,etc.

A 12-lane stick pack machine is ideal for businesses needing high-speed, single-dose packaging with precision and efficiency. When selecting a machine, consider speed, flexibility, and compatibility with your product.