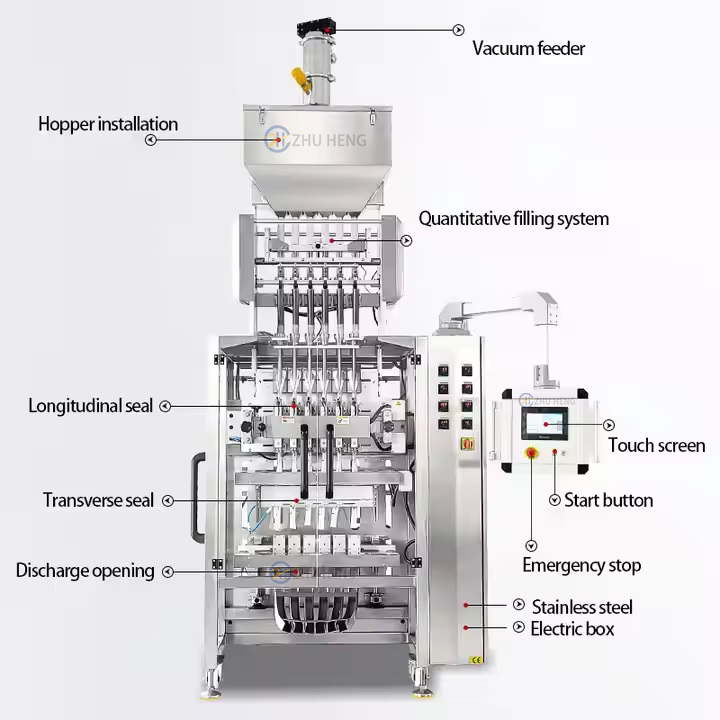

Multi-Lane Packaging Machines are an automated system designed to handle multiple parallel production lanes, allowing simultaneous packaging of products at high speeds.2-12 Row Packaging Machines are widely used in pharmaceuticals, food, cosmetics, and consumer goods industries to improve efficiency and reduce production time.

Key Features of Multi-Lane Packaging Machines

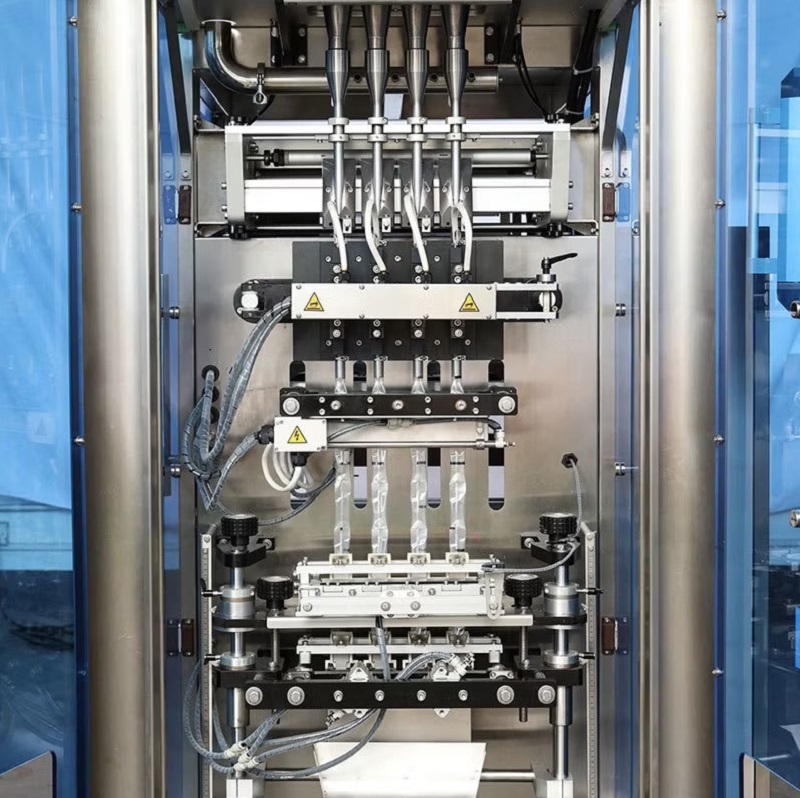

✔ High-Speed Operation – Processes multiple lanes (2 to12 lanes) in parallel, significantly increasing output.

✔ Flexible Lane Configuration – Adjustable for different container types.

✔ Automated Feeding & Sorting – Vibratory bowls, conveyors, or robotic systems feed products into each lane.

✔ Integrated Quality Control – Includes checkweighing, metal detection.

✔ Quick Changeover – Easy switching between product formats with minimal downtime.

✔ PLC/HMI Control – User-friendly touchscreen for monitoring and adjusting settings.

Common Applications

Pharmaceuticals – Filling and sealing tablets, capsules,powder in multiple lanes.

Food & Beverage – Packaging candies, nuts, powders, or liquids in sachets.

Cosmetics & Personal Care – Handling creams, serums, and travel-sized products.

Advantages Over Single-Lane Machines

✅ Higher Throughput – Processes 2x–12x more products per minute.

✅ Space Efficiency – Compact design compared to multiple single-lane machines.

✅ Lower Labor Costs – Reduces manual handling and supervision.

✅ Better Consistency – Uniform packaging quality across all lanes.

Tag:2-12 Row Packaging Machines,Multi-Lane Packaging Machines,Packing Machine