1. Introduction

Multi-lane Packaging Machine is an efficient and flexible automated packaging equipment, which is widely used in food, pharmaceutical, daily chemical and other industries. Its core advantage is that it can simultaneously complete the metering, filling, sealing and slitting of multiple columns of products, significantly improving production efficiency. With the growth of intelligent manufacturing and flexible production demand, the technical iteration and innovation of multi-column packaging machines have become the focus of the industry.

2. Working principle of multi-column packaging machine

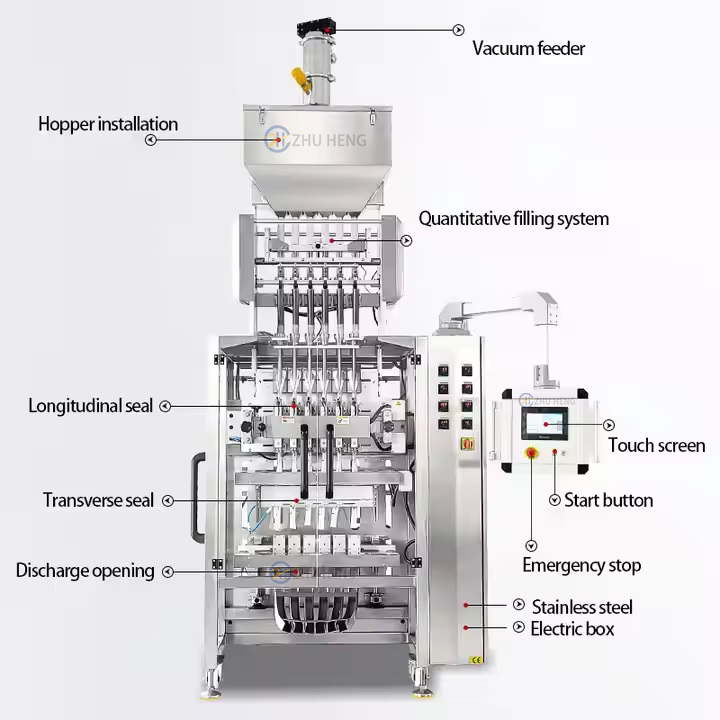

Multi-column packaging machine realizes high-speed continuous packaging by processing multiple columns of products in parallel. Its working process is as follows:

■Film unwinding: prefabricated roll film (such as composite film, aluminum-plastic film) is unfolded through the tension control system to ensure the flatness of the material.

■Bag forming: The film is folded into a multi-column cylinder by the former, and the side is pre-sealed by the heat sealing device.

■Product filling: The multi-column metering system (such as screw, measuring cup, electronic scale) synchronously fills the material into each column bag.

■Horizontal sealing and slitting: The horizontal heat sealing mechanism seals the bag mouth and cuts it into independent small packages.

■Output and stacking: Finished products are discharged through conveyor belts and can be connected to automatic case packers or palletizing systems.

Technical features:

■Parallel operation: Multiple columns are independently driven, with a speed of up to 50-60 packs/minute/column.

■High-precision metering: Servo control or weightless feeding is used, with an error of ≤±1%.

■Flexible production: Quickly switch packaging specifications (such as 1-12 columns) by changing molds.

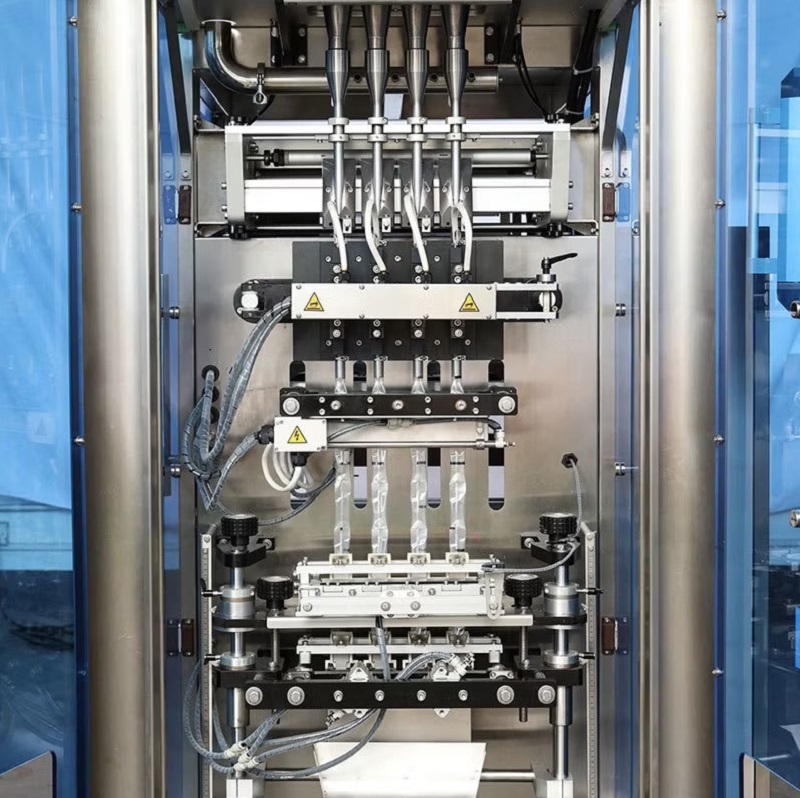

3. Core structure and key technologies

3.1 Mechanical system

■Multi-column former: Each column has an independent film guide mechanism to reduce material friction and deformation.

■Servo drive system: Each column uses an independent servo motor to ensure synchronization and speed flexibility.

■Heat sealing device: Pulse heating or constant temperature sealing, suitable for different film materials (such as PE, PET/AL/CPP).

3.2 Control system

■PLC+touch screen: Supports parameter preset, fault alarm and data recording.

■Visual inspection (optional): Detect sealing quality, printing date or missing filling problems.

■ IoT integration: access to MES system via OPC UA or Modbus protocol.

3.3 Metering system

■ Volumetric: screw metering (powder), measuring cup (granules) – low cost, high speed.

■ Weighing: electronic scale or loss-in-weight scale (high-value products such as medicines) – higher accuracy.

4. Application scenarios and industry cases

4.1 Food industry

■ Snack food: multi-row small packages of potato chips and nuts (such as 10g×8 rows).

■ Condiments: differentiated filling of sauce packs and instant coffee.

4.2 Pharmaceutical industry

■ Granules/tablets: multi-row synchronous packaging to meet GMP cleanliness requirements.

4.3 Daily chemical industry

■ Laundry beads: multi-chamber liquid filling and sealing.

■ Cosmetic trial packs: 1-5ml small dose precision packaging.

5. Selection points and common problems

5.1 Key parameters for selection

| Parameter | Description |

| Number of rows | 2-12 rows, select according to production capacity requirements |

| Packaging speed | Single row 50-60 bags/minute |

| Film width and bag length | Determine the maximum/minimum packaging size |

| Measuring method | Volumetric (low cost) vs. weighing (high precision) |

| Material adaptability | Whether anti-static and corrosion-resistant design is required |

5.2 Common problems and solutions

■ Film deviation: Install photoelectric deviation correction device.

■ Weak seal: Adjust temperature, pressure or replace heat sealing material.

■ Measuring error: Calibrate screw parameters or clean feeding system.

6. Future development trends

■ Intelligent upgrade: AI algorithm optimizes parameters and adapts to different material characteristics.

■ Sustainable packaging: Compatible with degradable films (such as PLA) and reduce waste film generation.

■ Modular design: Quickly switch functional modules (such as from vertical to pillow packaging).

■ Human-machine collaboration: Light robots assist in loading and unloading to reduce manual intervention.

7. Conclusion

Multi-row packaging machines have continuously improved efficiency and flexibility through technological innovation and have become an indispensable equipment for modern production lines. In the future, with the advancement of green packaging and Industry 4.0, its intelligent and environmentally friendly development direction will bring greater value to enterprises. When selecting a model, enterprises need to comprehensively consider production capacity, precision and scalability to match long-term production needs.

If you want to consult about Multi-row Packaging Machine, feel free to contact me~