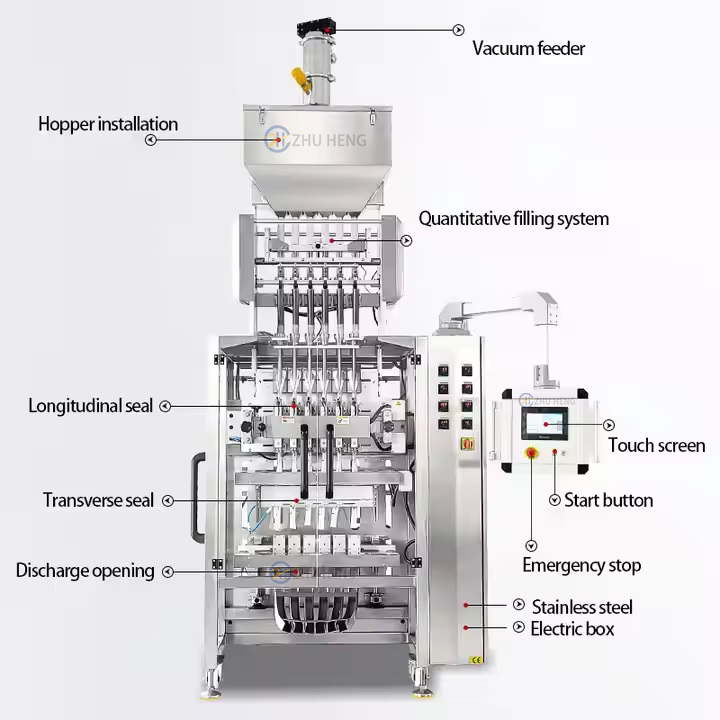

■ Product Introduction

The High-Speed 6-Lane Packing Machine is an automated device specifically designed for high-speed, small-dose, multi-bag packaging production. It is widely used in small-bag packaging in the food, condiment, pharmaceutical, health product, cosmetic, and chemical industries. The machine utilizes six synchronous working channels to achieve continuous multi-row forming, filling, and sealing, significantly improving production efficiency.Multi lane Packing Machine is suitable for small-bag packaging of various materials such as powders, granules, liquids, and sauces.

■ Tech Specifications

Number of lanes: 6 (4/8/10/12 lanes available upon request)

Packaging speed: 240–300 bags/min (depending on material, bag type, and dosage)

Measuring range: 0.2g – 20g (customizable based on screw/pump/measuring cup)

Applicable materials: Powders, granules, liquids, pastes, small-dose solids

Bag width range: 20–60 mm (customizable per column)

Bag length range: 0–160 mm (adjustable)

Bag type: Three-side seal / Four-side seal / Back seal (pillow type) / Stick Pack

Bag width error: ≤ ±1 mm

Measuring accuracy: ≤ ±0.5–1% (depending on material type)

Sealing method: Heat sealing (temperature controlled)

Wrap width: Max 480–500 mm (depending on machine configuration)

Film material: PET/PE, paper film, aluminum foil composite film, heat-sealable film, etc.

Wrap diameter: Max 350 mm Air source requirement: 0.6 MPa (clean compressed air)

Power supply: AC 220V / 380V, 50/60Hz (customizable)

Power: 4.0–6.5 kW (depending on configuration)

Content material: 304/316 stainless steel (GMP standard)

Control system: PLC + touch screen HMI (Chinese and English)

For reference only, please contact us for specific information~

■ Main Features

1. Six-Channel Synchronous High-Speed Packaging

Six packaging channels can operate simultaneously, achieving high-volume output;

Standard speed can reach 240–300 bags per minute (varies depending on material and specifications);

Independent drive system ensures consistent sealing quality across all channels.

2. Multi-Pouch Forming and Sealing

Supports various pouch sizes and shapes:

Three-side seal

Four-side seal

Back seal (pillow type)

Strip/rod pouches

3. High-Precision Automatic Metering System

Different metering methods are available depending on the product:

Screw metering (powder)

Measuring cup metering (granules)

Piston pump/gear pump (liquids, pastes)

Micro-filling system (pharmaceutical grade)

4. Automatic Filling and Sealing

Automatically completes bag making, opening, filling, heat sealing, and bag cutting processes;

Constant temperature sealing system ensures a strong and airtight seal;

Supports photoelectric tracking for precise positioning of printed patterns.

5. Sanitary Design

304/316L stainless steel construction;

Material contact parts can be quickly disassembled and are easy to clean.

6. Intelligent Control System

PLC + HMI touchscreen interface;

Enables parameter memory, data statistics, and production recording.

■ Application

■ Package & Shipping

Inner use the plastic wrapping ,out package will use stronger wooden cases.

Our standard package process:

1) Dust & Cleaning

2) Lubricate Drive Parts

3) Divide Machine Into Modules

4) Wrap Modules With Plastic Film

5) Packing Modules into Plywood Cases

6) Mark Shipping Mark In The Cases

If any special requirements, we will pack it as requested.

■ FAQ

1.Tell me about your product details:

●What kind of product you have.

● the size of your product.

●What’s the weight of your product.

●What’s the speed requirement?

2.How easy is it to operate packaging equipment?

The good news is that as long as your packaging system isn’t hyper-customized, the equipment is pretty easy to use! Most of our equipment does not require advanced technical knowledge to operate.

3.How much does 6 line Packaging Machine cost?

There is no quick, easy answer to this question. Packaging machinery is specific to the customer, so arriving at ‘standard pricing’ isn’t usually practical. Pricing largely depends upon your unique needs, such as the products you want to package, the speeds you would like to achieve, your sizes or the complexity of your process. Contact us to get a specific quote.

4.Which machines are available in-stock?

If your needs are fairly standard and straightforward, you may be able to snag an In-Stock Machine and get it delivered in just a few weeks! Contact us to ask about our current inventory.

5.What is your after sales services?

● After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools.

● After the commissioning, we will package the equipment by standard export package for shipment.

● Engineers, sales managers and after-sales service managers will form an online after-sales team to follow up on customers’ projects.

TAGS:

Multi Lane Granule Packing Machine

Multi Lane Liquid Packing Machine

Multi Lane Powder Packing Machine

Multi Lane Sauce Packing Machine