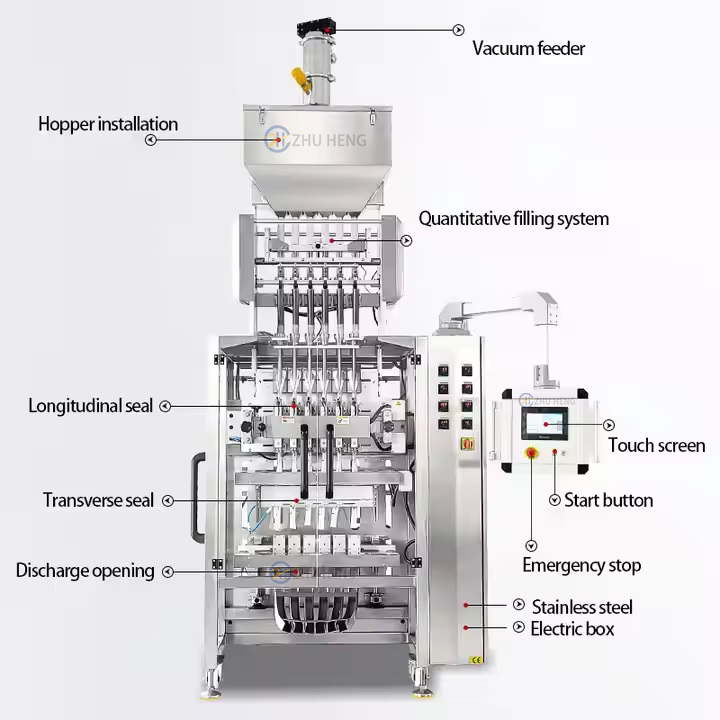

With the continuous advancement of packaging automation technology, demand for high-speed, high-precision multi-lane packaging equipment is growing. To meet this market trend, our company has officially launched a new generation of 4-lane Automatic Packaging Machines. With high efficiency, stability, and intelligent control, we provide customers with more competitive packaging solutions.

1. Highly Efficient Multi-lane Design, Doubled Capacity

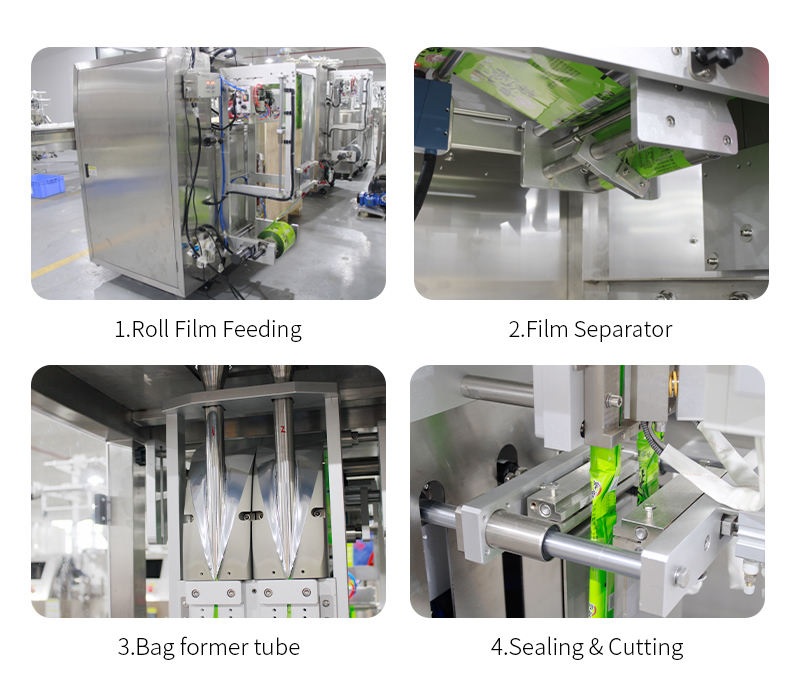

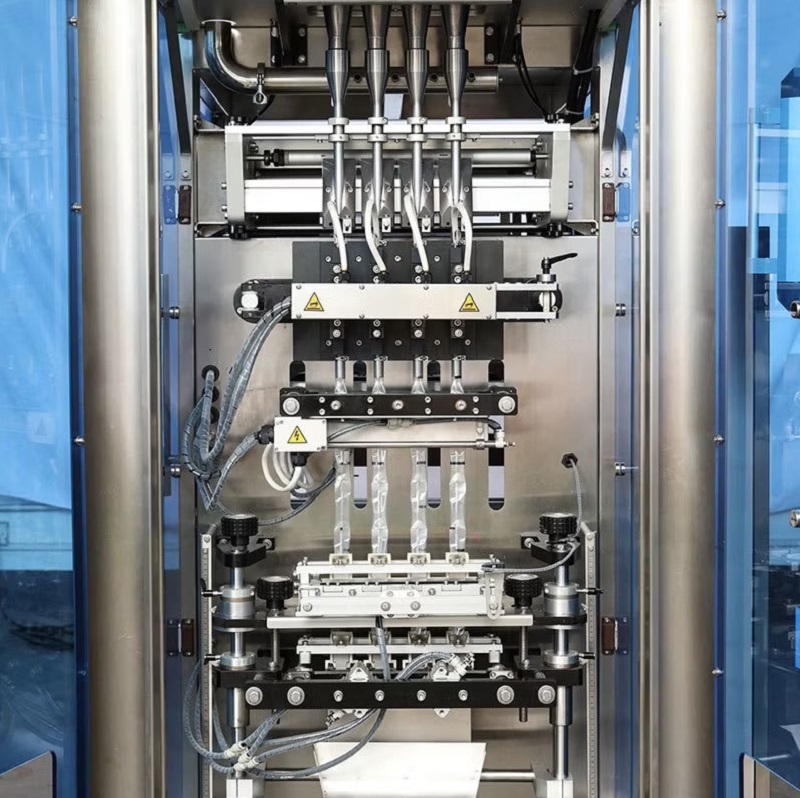

This machine utilizes four parallel lanes to simultaneously complete bag making, metering, filling, sealing, and cutting processes. Compared to traditional single-lane equipment, this increases capacity by 3 to 4 times, effectively meeting the high-speed packaging needs of small bags in the food, pharmaceutical, and daily chemical industries.

2. Intelligent Control System, Easy Operation

The machine is equipped with a high-performance PLC control system and a touchscreen human-machine interface, supporting parameter storage and fast switching. Multiple servo motors and a temperature control system ensure smooth sealing and precise cutting, ensuring a uniform appearance and reliable seal for each bag.

3. Versatile Compatibility, Wide Applicability

The machine can be used with metering devices for powders, granules, liquids, or pastes, flexibly adapting to a variety of packaging materials. All contact parts are made of 304 stainless steel, complying with GMP hygiene standards and ensuring safety, hygiene, and easy cleaning and maintenance.

4. Expandable Intelligent Connection

The four-row automatic packaging machine can be interconnected with checkweighers, metal detectors, printing systems, and automatic case packing lines to create a complete intelligent packaging production line, enabling factories to achieve digital and unmanned upgrades.

Our company will continue to focus on the research and development of automated packaging technology, providing efficient, intelligent, and reliable packaging equipment solutions to customers worldwide.

TAGS