Automatic Sauce Vertical Form Fill And Seal Multi lane Packing Machine for Sachet Shampoo uses advanced technology to efficiently weigh and dispense product into bags, optimizing productivity. It is ideal for a wide range of industries requiring high-speed packaging solutions.

Track Number:2~12 Track

Filling Method:1.Piston pump; 2.Peristaltic Pump

Capacity:Max.40 cycle/min

Sachet Size:L:45–120mm; W:35-120mm

Film Width & Thickness:Max.960mm;0.07-0.1mm

Sealing Type:3/4 sides sealing

Cutting Type:1.Straight Cutting;2.Zig Zag Cutting;3.Continuous Cutting

Air & Power:0.8 mpa 0.8m3/min; 5.5kw

For reference only, please consult for details!

Contact us to recommend a product that is suitable for you!

1. Automatically complete all tasks such as measurement, bag making, filling, sealing, batch number printing, cutting and counting.

2. Automatic slitting film system, multi-line row and bag sealing at the same time.

3. Servo film running system, pneumatic control for horizontal sealing, accurate positioning, remarkable performance and beautiful packaging.

4. The dual light source photoelectric detection system is stable and reliable to ensure the integrity of the packaging bag.

5. Intelligent PLC control system, stable operation of the machine, convenient and fast operation,

6. A variety of automatic alarm protection functions can effectively reduce the loss of materials and ensure work safety.

7.2 to 12 lanes can be packed according to the width of the bag.

Sauce Multi lane Packing Machine, packaging solutions for bags such as sauce, miso paste, tomato sauce, olive oil, syrup, peanut butter, chocolate sauce, ketchup, shampoo, etc.

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

1.Before the products are sold, we will go through strict inspection,and the products you sign for have no quality problems.

2.The products provided to customers are all produced by the original factory, and have factory data accessories.

3.During the warranty period, our company will repair the damaged parts due to quality reasons, and the damage of the parts outside the warranty period. The provided accessories only charge the cost. If the equipment is damaged due to human factors, the parts repaired or provided by our company are calculated at the cost.

FAQ

Q1.Are you a manufacturer or trader?

A: Shanghai Zhuheng Industiral Co,. Ltd is a manufacturer, located in Shanghai, China. We have our own product design team.

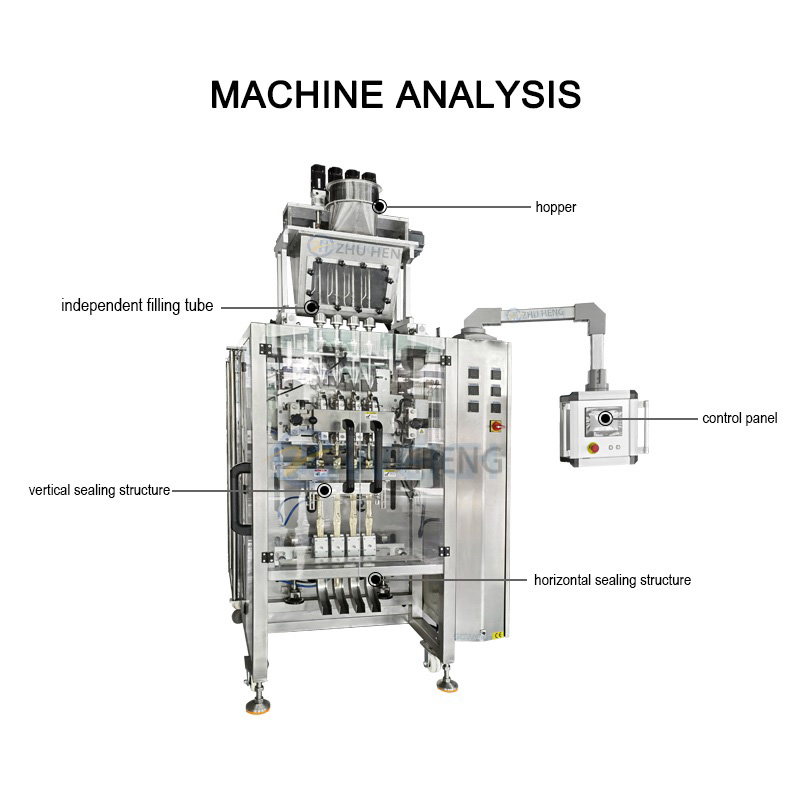

Q2.What are the typical components of a multi-lane packing machine?

Feeding system: Delivers materials to be packaged.

Metering system: Measures the product for consistent filling.

Bagging system: Forms and seals the packaging bags.

Control system: Manages the entire packaging process.

Discharge system: Conveys finished packages out of the machine.

Q3.What factors should I consider when choosing a multi-lane packing machine?

The type of product you will be packaging

Your desired production speed

The size and weight of your packages

Q4. What kind of shipping methods can you provide?

A: By sea, by air and by international express. After confirming your order, we will update you the production details by email and photos.

Q5. Do you accept customer logos and customization?

A: We accept all kinds of customization and logos for all products.

Q6. How about the product packaging? Is it easy to be damaged during transportation?

A: No. We use wooden boxes, which are very safe.